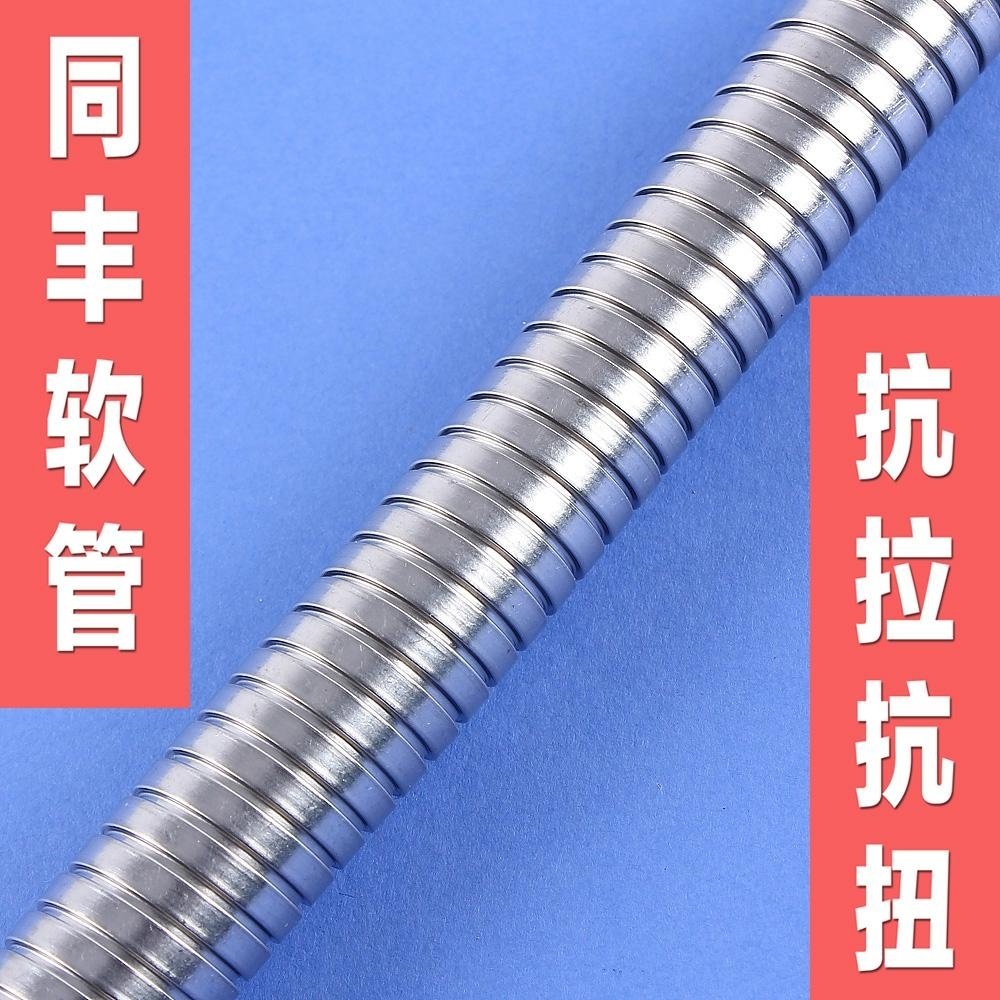

TongFengflex manufactures unique tubing that is relied on in numerous industries. The tubing is produced by helical coiling of metal strip onto a spindle, with the helical coils being linked with each other by means of a special type of strip profile. Basic materials for the strip are stainless steel. However, other metals are also available.

Applications: Instrumentation tubing is used by manufacturers of various industries, such as Process & Control Instrumentation, Measuring & Controlling Devices, Analytical Instruments, Medical Instruments and many others with specific applications including temperature measuring, wiring conduit or armor cable and protective casing.

Instrumentation tubing is made in two configurations, or constructions, commonly called SquareLok and InterLock, and is often abbreviated as TF-D and TF-S.

Technical Data:

SquareLok Style (TF-D)SquareLock tubing is produced from a continuous metal strip, and is held in position by locking one leg of one profile over the leg of the adjacent profile.

| TYPE |

ID |

OD |

Tolerance +/-

|

Weight ] |

Bending radius |

Load strength |

Tensile strength |

| TF-D0406 |

4 |

6 |

0.1 |

0.034 |

15 |

800 |

320 |

| TF-D0507 |

5 |

7 |

0.1 |

0.039 |

17 |

835 |

340 |

| TF-D0608 |

6 |

8 |

0.1 |

0.044 |

19 |

875 |

360 |

| TF-D0709 |

7 |

9 |

0.1 |

0.049 |

20 |

930 |

380 |

| TF-D0810 |

8 |

10 |

0.1 |

0.056 |

22 |

975 |

400 |

| TF-D0911 |

9 |

11 |

0.1 |

0.063 |

25 |

1020 |

450 |

| TF-D1013 |

10 |

13 |

0.1 |

0.100 |

30 |

1060 |

500 |

| TF-D1114 |

11 |

14 |

0.1 |

0.110 |

31 |

1095 |

550 |

| TF-D1215 |

12 |

15 |

0.1 |

0.120 |

32 |

1140 |

600 |

| TF-D1316 |

13 |

16 |

01 |

0.130 |

33 |

1175 |

650 |

| TF-D1417 |

14 |

17 |

0.1 |

0.140 |

35 |

1215 |

700 |

| TF-D1518 |

15 |

18 |

0.1 |

0.150 |

37 |

1250 |

720 |

| TF-D1619 |

16 |

19 |

0.1 |

0.160 |

40 |

1290 |

760 |

| TF-D1720 |

17 |

20 |

0.1 |

0.170 |

45 |

1330 |

800 |

| TF-D1821 |

18 |

21 |

0.1 |

0.180 |

42 |

1470 |

890 |

| TF-D1923 |

19 |

23 |

0.2 |

0.212 |

40 |

1510 |

840 |

| TF-D2024 |

20 |

24 |

0.2 |

0.223 |

42 |

1545 |

890 |

| TF-D2125 |

21 |

25 |

0.2 |

0.235 |

45 |

1580 |

920 |

Fully InterLock Style (TF-S) InterLock metal strip and the edges of the strip are completely interlocked with each other. This offers increased crush protection, and higher axial strength.

| TYPE |

ID |

OD |

Tolerance +/- |

Weight

|

Bending radius |

Load strength |

Tensile strength |

| TF-S0406 |

4 |

6 |

0.1 |

0.053 |

25 |

900 |

200 |

| TF-S4267 |

4.2 |

6.7 |

0.1 |

0.066 |

28 |

955 |

285 |

| TF-S5378 |

5.3 |

7.8 |

0.1 |

0.079 |

32 |

1000 |

395 |

| TF-S5580 |

5.5 |

8 |

0.1 |

0.082 |

35 |

1050 |

400 |

| TF-S5984 |

5.9 |

8.4 |

0.1 |

0.086 |

38 |

1185 |

450 |

| TF-S6590 |

6.5 |

9 |

0.1 |

0.093 |

40 |

1125 |

500 |

| TF-S8011 |

8 |

11 |

0.1 |

0.141 |

45 |

1275 |

700 |

| TF-S9012 |

9 |

12 |

0.1 |

0.159 |

50 |

1340 |

800 |

| TF-S1013 |

10 |

13 |

0.1 |

0.177 |

55 |

1415 |

900 |

| TF-S1114 |

11 |

14 |

0.1 |

0.195 |

65 |

1480 |

1000 |

| TF-S1215 |

12 |

15 |

0.1 |

0.213 |

70 |

1550 |

1100 |

| TF-S1316 |

13 |

16 |

0.1 |

0.230 |

75 |

1620 |

1200 |

| TF-S1417 |

14 |

17 |

0.1 |

0.248 |

80 |

1690 |

1300 |

| TF-S1518 |

15 |

18 |

0.1 |

0.265 |

82 |

1765 |

1400 |